Danielle Tan

Chief Operating Officer

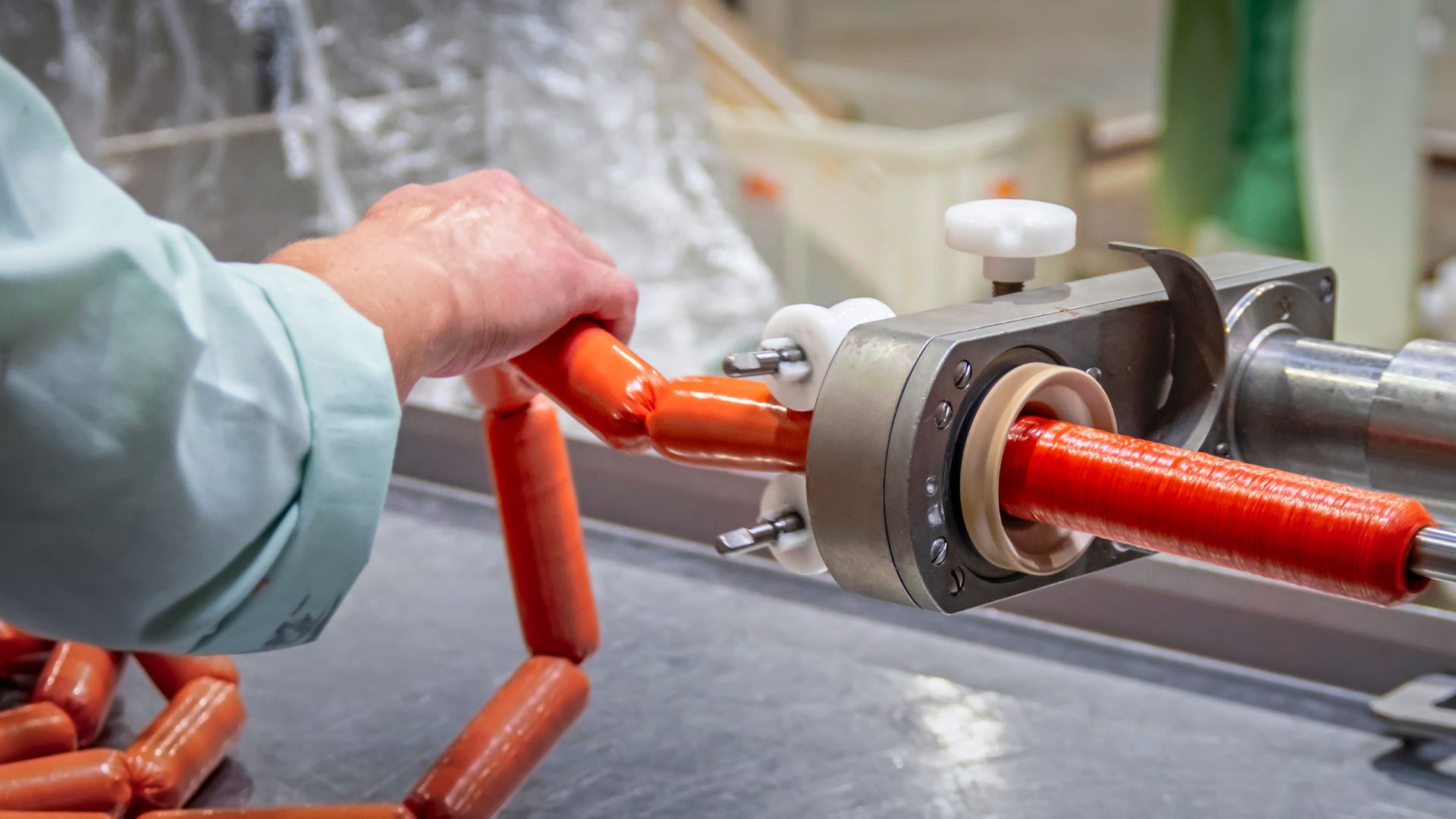

Learn about the latest guidelines in FSSC 22000 Version 6 for effective equipment management, ensuring safety, efficiency, and compliance in food production facilities.

One of the new requirements in FSSC 22000 version 6 is equipment management, which is defined under clause 2.5.15 in the FSSC 22000 additional requirement. It is applicable to all food chain categories, except subcategory FII on brokering and trading.

2.5.15 Equipment Management

In addition to clause 8.2.4 of ISO 22000:2018, the organization shall:

- Have a documented purchase specification in place, which addresses the hygienic design, applicable legal and customer requirements, and the intended use of the equipment, including the product handled. The supplier shall provide evidence of meeting the purchase specification prior to installation.

- Establish and implement a risk-based change management process for new equipment and/or any changes to existing equipment, which shall be adequately documented, including evidence of successful commissioning. Possible effects on existing systems shall be assessed, and adequate control measures determined and implemented.

According to GFSI, equipment is defined as machines and equipment (including their parts and components necessary for their operation), feed and food transport systems, and food storage and display units for processing and retailing food, feed, and packaging materials within GFSI recognition scopes.

General Requirements

This requirement pertains to significant changes in equipment that can impact its hygienic design. It does not include maintenance activities like changing a fuse or replacing a fraying conveyor belt, which are covered under the maintenance section of the relevant PRP sector-specific standard, such as clause 8.6 of ISO/TS 22002-1. However, modifications such as adding an extra conveyor belt to speed up production are considered significant changes, necessitating a review of the existing line’s design and a hygienic design risk assessment.

Purchase Specification

In accordance with 2.5.15 (a), an organization must have a documented purchase specification that addresses hygienic design, applicable legal and customer requirements, and the intended use of the equipment, including the product handled.

To ensure effective food safety management, it is crucial that expectations and interpretations of needs, capabilities, and intended use are clear during the development, realization, or handover of food processing equipment when newly purchased from the manufacturer.

The organization must document a purchase specification for each piece of equipment before purchasing it. This specification should address the specific hygienic design parameters for the type of equipment being ordered or manufactured.

The intended use of the equipment must be specified, including the product handled. To establish the purchase specification, the organization should conduct an equipment design risk assessment considering the equipment’s intended use, food safety hazard identification, and risk assessment.

Once the intended use is known and the risks related to the type of products to be packed or manufactured have been identified through the risk assessment, the hygienic design principles required to ensure food safety should be adopted and specified within the purchase specification. Specific customer and legal requirements must also be incorporated into the purchase specification.

The equipment design must ensure it is suitable for the intended use and minimize potential product contamination. Recognized hygienic design standards for the specific industry should be considered. The specification must be documented and implemented every time new equipment is planned for purchase.

Organizations should include a requirement in the purchase specification that equipment manufacturers must inform them of any food safety risks that cannot be eliminated by hygienic design. Additionally, manufacturers must provide an instruction manual with information necessary for the hygienically safe operation of the equipment within its intended use. This manual should include:

- Instructions regarding limitations and operational use

- Instructions regarding technical measures (e.g., control or inspection devices)

- Instructions on disassembling for inspection, cleaning, and maintenance

- Cleaning instructions

For changes to existing equipment or custom-made equipment by the Certified Organization’s engineers or maintenance technicians, specifications can be developed using expertise from various departments within the Food Safety Team. If internal expertise is lacking, external experts can be consulted.

Key considerations should include the hygienic design of materials used for construction, such as stainless steel, smooth and continuous welding edges, avoiding fasteners in or above the product contact zone, rounding piping and ductwork to prevent dead ends, mounting on legs or wheels for easy cleaning, and ease of disassembly for deep cleaning.

A service-level agreement should be established between the supplier/manufacturer and the purchasing organization.

In acordance with 2.5.15 (a), the supplier must provide evidence of meeting the purchase specification prior to installation. The equipment manufacturer/supplier must demonstrate compliance with the purchase specifications and requirements, including any customer and regulatory requirements. This can be verified by comparing the manufacturer’s manual with the purchase specification and maintaining evidence of this review.

Risk-based Change Management Process

In accordance with 2.5.15 (b), an organization must establish and implement a risk-based change management process for new equipment and/or changes to existing equipment. This process must be thoroughly documented, including evidence of successful commissioning.

The objective of change control is to manage changes in a way that foresees and addresses their impact on food safety, ensuring appropriate mitigation actions and control measures are executed.

Change control involves the organization conducting a risk assessment, determining risk mitigation based on hygienic design principles, and documenting the changes. The Food Safety Team should ensure relevant managers are aware of these requirements to ensure the change management process is followed.

Installation and Commissioning Phase:

- Installation: During installation, verify that the correct equipment has been received and installed according to the approved specification. For equipment prefabricated at the supplier’s site, a factory acceptance test (FAT) should be performed by the purchasing organization at the supplier’s site before delivery.

- Commissioning: After installation and before use, verify that all functional parameters, specifications, limits, and tolerances detailed in the purchase specification and user manual/guide are met to achieve the required hygienic performance. A site acceptance test (SAT) should be conducted after installation and commissioning, including functional testing.

- Validation Study: The organization should conduct a validation study to confirm that newly installed equipment functions as designed according to the manual/guide, including aspects of food safety, quality, cleanability, and cleaning validation activities. This validation should be completed as part of the process qualification, considering planned or projected usage in production.

Although separate from the FSSC 22000 additional requirement, it is recommended that existing equipment not previously evaluated for hygiene-related performance undergo hygienic design risk assessments and retrospective cleaning validation based on historical data. Based on the risk assessment, the organization should conduct a cleaning validation of the equipment to determine if the cleaning is appropriate or if changes to the cleaning program are needed to ensure hygienic operation.

When implementing this requirement for equipment change management, consider clause 6.3 of ISO 22000:2018. Organizations should incorporate the risk-based change management process for equipment into the existing change management process within the FSMS. Changes should be documented according to the existing process, noting the requirements of clause 6.3 for retained evidence.

In accordance with 2.5.15 (b), possible effects on existing systems must be assessed, and adequate control measures determined and implemented.

The organization must assess the impact of equipment changes/modifications to determine if they alter or increase the risk of existing hazards identified in the hazard analysis or introduce new hazards. If so, the organization must evaluate and amend current control measures as needed (e.g., increase monitoring frequency) or establish additional control measures.

Conclusion

If Equipment Changes are Planned, Consider the Following:

- Update the hazard analysis.

- Update the cleaning and sanitation program (procedures, cleaning schedules, records). Determine if outsourced services are needed or if they can be done internally.

- Update the maintenance program (procedures, maintenance schedules, equipment checks) and determine if outsourced services are needed or if they can be done internally.

- Update production records, if necessary.

- Review and update the environmental monitoring program.

- Review and update the allergen management program, if applicable.

- Review and update the training program and train relevant personnel on updated procedures.

- Update any other relevant verification activities.

- Determine if additional resources are needed and their availability in case of breakdowns or faulty operations with the equipment.

Reference:

- Food Safety System Certification 22000 Guidance Document: Equipment Management.

Curious to learn how to manage your factory equipment? Get in touch with us now for more information.